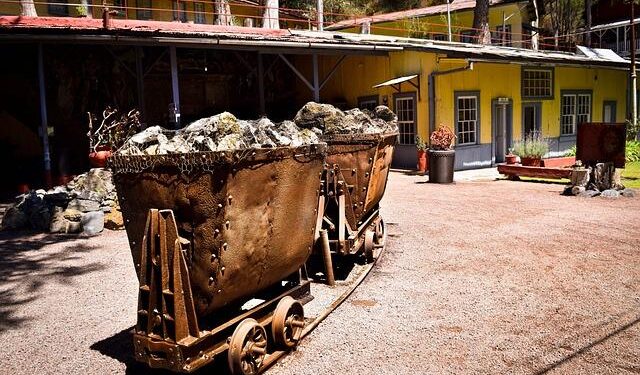

In a important advancement in lasting mining practices, Boliden has officially inaugurated what it claims to be the world’s most climate-efficient zinc smelter in Norway.This ambitious project, located in the scenic region of Kvaryd, aims to revolutionize zinc production by substantially reducing greenhouse gas emissions and energy consumption. As the global demand for zinc continues to rise, Boliden’s innovative approach not only positions the company as a leader in eco-friendly mining but also sets a new benchmark for the industry. The smelter’s cutting-edge technology, combined with a commitment to environmental stewardship, underscores the growing importance of sustainability in the mining sector, as companies strive to align with global climate objectives. In this article, we explore the features of Boliden’s new facility, the technological advancements driving its efficiency, and the broader implications for the future of mining and metal production.

Bolidens Commitment to Sustainability in Zinc Production

Boliden’s latest zinc smelter in Norway sets a new benchmark for sustainability in the mining industry.By leveraging cutting-edge technology, the facility is designed to operate with significantly reduced carbon emissions compared to traditional methods. This commitment to environmental stewardship is reflected in key operational strategies that emphasize both energy efficiency and resource optimization. Among the initiatives undertaken,the adoption of renewable energy sources and advanced smelting techniques play pivotal roles in minimizing the ecological footprint of zinc production.

In pursuit of transparency and accountability, Boliden is committed to achieving strict sustainability targets throughout its operations. The following core principles guide the company’s efforts:

- Reduction of Greenhouse Gas Emissions: Implementing process innovations to curtail carbon emissions.

- Water Conservation: Utilizing closed-loop water systems to recycle and minimize water usage.

- Waste Management: Prioritizing recycling and safe disposal of byproducts to protect surrounding ecosystems.

To demonstrate its progress, Boliden regularly publishes sustainability reports that detail their objectives and outcomes, fostering a culture of continuous improvement in not just zinc production, but in the broader mining sector as well.

Innovative Technologies Driving Climate Efficiency at the New Smelter

The recent inauguration of the zinc smelter in Norway marks a significant leap in adopting innovative technologies aimed at enhancing climate efficiency. At the heart of this project lies the integration of advanced technologies that minimize greenhouse gas emissions while maximizing resource utilization. Key advancements include:

- Hydrogen-based processes: Utilizing hydrogen as a reducing agent in zinc production drastically cuts CO2 emissions associated with traditional methods.

- Circular economy principles: Implementing recycling systems to recover materials from industrial waste contributes to a more sustainable operation.

- Energy-efficient equipment: Smart machinery and techniques have been deployed to optimize energy consumption,reducing overall resource input.

Moreover, the smelter features a highly optimized cooling and heating system that harnesses renewable energy sources, further driving down its carbon footprint.The integration of digital technologies also plays a crucial role in operational efficiency by enabling real-time data monitoring and predictive maintenance. Some notable technological components include:

| Technology | Impact |

|---|---|

| Intelligent Automation | Increased operational efficiency |

| Carbon Capture Utilization | Reduces emissions by reusing CO2 |

| Data Analytics | Enhances process optimization |

impact of the Zinc Smelter on Global Environmental Standards

The inauguration of Boliden’s new zinc smelter in Norway sets a landmark precedent for global environmental standards within the mining and metallurgy sectors.This facility is touted as the “world’s most climate-efficient” due to its innovative technology that significantly reduces greenhouse gas emissions. By incorporating state-of-the-art equipment and sustainable practices, the smelter achieves a reduction in CO2 emissions by up to 30% compared to traditional zinc smelting processes.Such advancements not only challenge existing industry norms but also raise the stakes for other facilities worldwide to follow suit in the pursuit of more sustainable operations.

Moreover, the impact of this smelter extends beyond its immediate operations. It serves as a model for future investments in green technologies and encourages a shift towards stricter regulatory measures across the globe.Key advantages of the new smelter include:

- Enhanced energy efficiency: Utilization of renewable energy sources reduces dependency on fossil fuels.

- Waste management innovation: Improved techniques for recycling process waste contribute to a circular economy.

- Transparency in operations: High standards of reporting and environmental compliance to gain public trust.

As other mining companies draw inspiration from Boliden’s achievements, this smelter not only promotes environmental stewardship but also highlights the economic viability of adopting sustainable technologies within the sector. The ripple effects could encourage global leaders to implement more rigorous environmental standards,ultimately benefiting both industry stakeholders and the planet.

economic and Social Benefits of the New Facility in Norway

The inauguration of the new zinc smelter in Norway marks a significant milestone, not only in terms of environmental efficiency but also in the broader economic landscape. The facility promises to enhance local employment opportunities,creating jobs that will stimulate the community. Key economic advantages include:

- Increased job creation in both the construction and operational phases.

- Boosting local businesses through increased demand for goods and services.

- Attracting foreign investment, positioning Norway as a leader in sustainable mining practices.

From a social outlook, the facility will likely contribute to improved community well-being and educational initiatives. The company has committed to engaging with local educational institutes to promote skills development in the mining and environmental sectors. anticipated benefits include:

- Partnerships with universities for research and innovation in sustainable practices.

- Greater community involvement through outreach programs and consultation.

- Enhanced quality of life as local infrastructure is improved to support the facility and its workforce.

Future Prospects for Climate-Efficient Mining operations

the inauguration of the world’s most climate-efficient zinc smelter in Norway by Boliden marks a significant milestone in the mining industry, showcasing a proactive shift towards sustainable practices. This facility is equipped with cutting-edge technologies aimed at minimizing carbon emissions and optimizing energy use.Key features of this innovative smelter include:

- Renewable energy sources: Harnessing solar and wind energy to power operations.

- Advanced smelting technology: employing methods that reduce energy consumption significantly.

- Recycling initiatives: Incorporating a process for recycling materials, thereby reducing raw material extraction.

The establishment of this facility serves as a blueprint for future mining operations seeking to align with global climate goals. The implications of such advancements extend beyond operational efficiencies; they also set a precedent for regulatory and market shifts. As sustainability becomes an essential criterion for investment and consumer choice, companies are likely to adopt similar practices. Future mining ventures might emphasize:

- Innovative partnerships: Collaborating with technology firms to enhance efficiency.

- Regenerative practices: Focusing on restoration projects that aid in carbon sequestration.

- Transparent reporting: Sharing data on emissions and sustainability efforts to earn consumer and investor trust.

Recommendations for Industry-Wide Adoption of Green Practices

In light of Boliden’s groundbreaking achievement with its zinc smelter, it is imperative for the industry to embrace similar sustainable practices across the board. Collaboration among key stakeholders—including mining companies,government bodies,and environmental organizations—is essential for the effective dissemination and implementation of green technologies. Setting up shared platforms for exchanging insights and best practices can accelerate the transition. Additionally, investment in research and development focusing on innovative processing techniques that minimize emissions and waste will be critical in propelling the industry towards a greener future.

Moreover, the establishment of incentives and regulatory frameworks that encourage environmentally friendly methods can galvanize wider adoption. This approach could include financial incentives for companies that meet specific sustainability benchmarks or adopt new technologies. A concerted effort to educate both industry leaders and the workforce on sustainable practices will further enhance this transition. Below is a simple overview of potential recommendations:

| Recommendation | Description |

|---|---|

| Collaboration | Engage stakeholders to share best practices. |

| Investment in R&D | Focus on innovative and sustainable processing techniques. |

| Incentives | Establish financial rewards for achieving sustainability goals. |

| Education | Provide training on sustainable practices for industry workers. |

Future Outlook

Boliden’s inauguration of what is touted as the world’s most climate-efficient zinc smelter in Norway marks a significant milestone in the mining industry’s commitment to sustainability. This state-of-the-art facility not only showcases innovative technologies designed to minimize carbon emissions but also reinforces the company’s dedication to environmental duty amidst growing concerns about climate change. As global demand for zinc continues to rise, Boliden’s efforts may set a new benchmark for eco-friendly practices in mineral extraction and processing. The ramifications of this project extend beyond operational efficiency; they resonate with broader industry trends aimed at achieving a greener future. Stakeholders and environmental advocates alike will undoubtedly be watching closely to see how this initiative shapes the future of zinc production and inspires further advancements in sustainable mining practices worldwide.