Stellantis and Leapmotor are reportedly leaning towards Spain as the production hub for their forthcoming B10 electric SUV, a strategic move that underscores the growing importance of the European market in the electric vehicle (EV) landscape. As the automotive industry grapples with an urgent shift towards sustainability and innovation,this partnership signals a commitment to enhance local manufacturing capabilities and cater to an increasingly eco-conscious consumer base.With Spain emerging as a pivotal player in the electric mobility sector, the choice of location for the B10 SUV’s production could help solidify the region’s status as a key manufacturing center in the global transition to electric vehicles. This article delves into the implications of this potential decision and what it means for both companies and the broader automotive market in Europe.

Stellantis and Leapmotor Collaborate for B10 Electric SUV in Spain

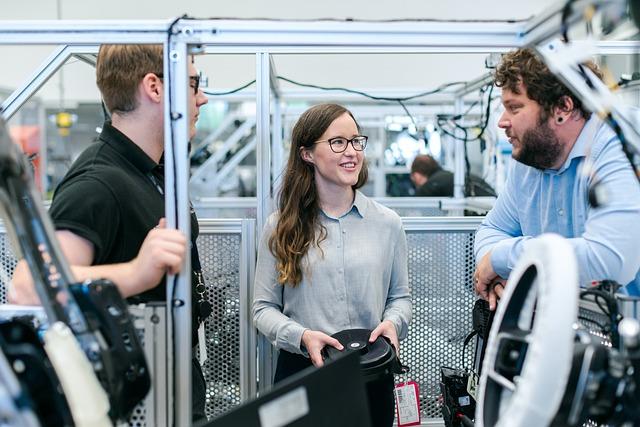

In a strategic collaboration, Stellantis and Leapmotor are set to bring the B10 electric SUV to life in Spain, a key move that underscores both companies’ commitment to the European electric vehicle market. This partnership aims to leverage Stellantis’ extensive manufacturing capabilities alongside Leapmotor’s innovative technology to create a vehicle that meets the growing demand for sustainable transportation solutions. As part of this initiative, several factors are being prioritized:

- Local Production: Enhancing job creation and economic growth in Spain.

- Environmental Goals: Aiming for a important reduction in carbon emissions.

- Market Insights: Utilizing local market knowledge to tailor the SUV to consumer preferences.

this collaboration is anticipated to roll out production by 2025 and is part of a broader strategy to establish a competitive edge in the rapidly evolving electric vehicle sector. According to industry sources, both companies are committed to sustainability, not just in the vehicles they produce but also in the production processes themselves. Key features of the B10 electric SUV are expected to include:

| Feature | Description |

|---|---|

| Battery Technology | Advanced lithium-ion battery with extended range. |

| smart Connectivity | integration of AI and IoT for enhanced user experience. |

| Eco-Pleasant Materials | Use of recycled and sustainable materials in construction. |

Strategic Benefits of Manufacturing Electric SUVs in Spain

Manufacturing electric suvs in Spain presents a multitude of strategic benefits that position the country as a key player in the rapidly evolving automotive industry. For global automakers like Stellantis and Leapmotor, Spain offers a strategic geographical location that facilitates efficient access to both European and African markets. This advantage is underpinned by well-established logistics networks and infrastructure, enabling streamlined supply chains. additionally, Spain’s commitment to sustainability aligns with the growing consumer demand for cleaner transportation alternatives, reinforcing the appeal of producing electric vehicles locally.

Furthermore, the Spanish government actively promotes investment in green technologies, providing incentives that make manufacturing electric SUVs not only feasible but also economically attractive.The availability of skilled labour, particularly in engineering and advanced manufacturing, enhances the potential for innovation and high-quality production. Key benefits include:

- Labor advantages: Access to a highly skilled workforce specialized in automotive technologies.

- Government Incentives: financial support and tax breaks for renewable energy initiatives.

- Supporting Supply Chain: Local suppliers can streamline production processes and reduce costs.

In pursuing the production of electric SUVs in Spain, both Stellantis and Leapmotor can leverage these strategic advantages to enhance their competitive edge while contributing to a greener automotive future.The interplay between local resources and government support creates a robust environment for innovation, making Spain a hub for electric vehicle manufacturing in Europe.

Exploring Spain’s Automotive Infrastructure for Electric Vehicle Production

Spain has emerged as a significant player in the global electric vehicle (EV) landscape,with an automotive infrastructure that is rapidly evolving to support production. Major manufacturers, like Stellantis and Leapmotor, are recognizing Spain’s strategic location, extensive industrial base, and a growing network of suppliers dedicated to electric mobility. The country’s existing automotive ecosystem, heavily rooted in customary manufacturing, is now pivoting towards electrification, which is essential for meeting future market demands. Key elements contributing to Spain’s attractiveness for electric vehicle production include:

- Robust Supply Chain: Spain’s automotive sector boasts an array of suppliers capable of supporting the specific needs of EV production, from battery technologies to electric drivetrains.

- Government Incentives: The Spanish government is actively promoting electric mobility through incentives aimed at both manufacturers and consumers, enhancing investment appeal.

- Skilled Workforce: A well-trained labor force in automotive manufacturing provides a competitive edge, facilitating the transition towards high-tech EV production.

- Infrastructure Investment: Ongoing investments in charging infrastructure across the country are expected to further bolster the growth of electric vehicle production and sales.

Additionally, the commitment of Spanish regional governments to support sustainable initiatives is fostering a favorable climate for innovations in electric vehicle technology. automotive hubs such as Barcelona and Valencia are becoming breeding grounds for new EV projects, where collaboration between academia and industry is yielding significant advancements. to illustrate the dynamic growth of EV production and the infrastructure supporting it, the following table outlines the major players and their respective contributions:

| Company | Production Focus | Key Location |

|---|---|---|

| Stellantis | B10 Electric SUVs | Madrid |

| Leapmotor | Electric Sedans | Valencia |

| Seat | Compact EVs | Barcelona |

Impact of B10 Production on Local Economies and Employment Rates

The decision by Stellantis and Leapmotor to establish B10 electric SUV production in Spain is poised to create a ripple effect on local economies and boost employment rates considerably. With the automotive industry being a cornerstone of Spain’s economy, the introduction of high-tech manufacturing capabilities will likely attract additional investment in the region, enhancing infrastructure and supporting local businesses. This move is expected to not only enhance competitiveness but also foster a sustainable environment for ancillary industries such as parts suppliers,service providers,and logistics companies.

moreover, the anticipated increase in job opportunities is set to resonate throughout the community. Positions will span across various skill levels, from engineering and design roles to assembly line and support staff. A preliminary analysis suggests a potential increase in local employment, with possible figures indicating:

| job Category | Estimated Jobs Created |

|---|---|

| engineering & Design | 300 |

| Manufacturing & Assembly | 1,200 |

| logistics & Supply Chain | 150 |

| Support Staff | 100 |

This influx of jobs has the potential to significantly reduce local unemployment rates, invigorating the workforce and fostering a sense of community pride. Beyond immediate employment opportunities, the long-term prognosis points towards sustainable economic growth, driven by innovation and the transition to electric mobility.

Environmental Considerations in Electric Vehicle Manufacturing in Spain

The manufacturing of electric vehicles (EVs) has significant environmental implications,particularly in regions where production capacities are expanding,such as Spain. As Stellantis and Leapmotor consider this location for their B10 electric SUV production, its critical to assess the environmental footprint of their operations. The key considerations include:

- resource Utilization: The extraction and processing of raw materials, such as lithium, cobalt, and nickel, essential for EV batteries can lead to environmental degradation if not managed properly.

- Energy Sources: Manufacturing facilities must prioritize renewable energy sources to power production lines, reducing greenhouse gas emissions and reliance on fossil fuels.

- Water Use: Efficient water management strategies are essential to mitigate the impact on local water supplies, especially in areas experiencing water scarcity.

Moreover, the adoption of sustainable practices during the manufacturing process can further enhance environmental stewardship.For instance,initiatives aimed at recycling battery components and promoting circular economy principles can significantly decrease waste. A summary of these sustainable practices can be outlined as follows:

| Practice | Impact |

|---|---|

| Battery Recycling | Reduces raw material demand and minimizes waste. |

| Use of Eco-Friendly Materials | Decreases carbon footprint during production. |

| energy Efficiency Measures | Lowers overall energy consumption and emissions. |

as Spain positions itself as a leader in EV manufacturing, the commitment to sustainability will not only enhance the industry’s reputation but also contribute to national and global environmental goals. Stakeholders must advocate for responsible practices that balance economic growth with ecological considerations.

Recommendations for Stakeholders to Enhance Spains EV Production Capabilities

To strengthen Spain’s position as a hub for electric vehicle production, stakeholders must consider a multifaceted approach. investment in infrastructure is crucial,with an emphasis on establishing advanced manufacturing facilities equipped with cutting-edge technology. The following strategies could significantly enhance Spain’s capabilities:

- Public-Private Partnerships: Foster collaboration between government bodies and private enterprises to co-finance EV-related projects.

- Skilled Workforce Development: Invest in education and vocational training programs focused on EV technology and manufacturing processes.

- Incentives for Research and Development: Provide tax breaks and grants aimed at promoting innovation in sustainable automotive technology.

Additionally, it is essential to establish a robust supply chain that ensures the availability of crucial components for electric vehicles. To facilitate this, stakeholders should prioritize:

| Component | Action Required |

|---|---|

| Battery Manufacturing | Encourage local production partnerships and ecosystem development. |

| Raw Materials | Secure sourcing agreements with suppliers to ensure steady access. |

| Charging Infrastructure | Accelerate installation of EV charging stations in urban and rural areas. |

In Retrospect

the reported preference of Stellantis and Leapmotor for Spain as the production site for their upcoming B10 electric SUV marks a significant step in the evolving landscape of electric vehicle manufacturing. This decision not only highlights Spain’s growing role as a hub for automotive innovation and sustainability but also reflects the increasing demand for electric vehicles in the European market. As both companies gear up to meet the challenges of an electrified future,the implications of this partnership and its geographical choice could resonate throughout the industry,potentially influencing future investments and strategies within the region. As developments unfold, stakeholders will be keenly watching how this collaboration shapes the trajectory of electric vehicle production in Europe.